How Much Does It Cost to Apply Concrete Floor Coatings?

Whether it’s in a basement, a garage, or the main floor of a house, many homeowners have at least some type of concrete flooring in their house. Concrete is a mix of cement and binders that forms a smooth, hard, and durable surface when cured. Concrete lasts for many years, but it needs to be properly attended to prevent cracks, staining, and wear and tear. Part of that care is either sealing or coating your concrete floor with a long-wearing topcoat.

You can coat your concrete floor in numerous ways. Some sealers and stains give it a new color and appearance, while others impact its longevity and do not alter its appearance in any way. These variations in coatings, coupled with the reality that concrete floors can be used in various areas and come in sizes, means that there is also a wide range of costs associated with coating a concrete floor. The national average cost range is $1,150 to $4,000, with most homeowners spending around $2,500 on an epoxy floor coating for a two-car garage floor. The project’s lowest cost is around $400 for a single coat of acrylic sealer on a single-car garage floor. This project’s highest cost is around $12,000 for a highly polished polymer overlay finish on the concrete flooring of a 1,000 sq. ft. loft.

| Concrete Floor Coating Cost | |

|---|---|

| National average cost | $2,500 |

| Average range | $1,150 - $4,000 |

| Minimum cost | $400 |

| Maximum cost | $12,000 |

Concrete Floor Coating Cost by Project Range

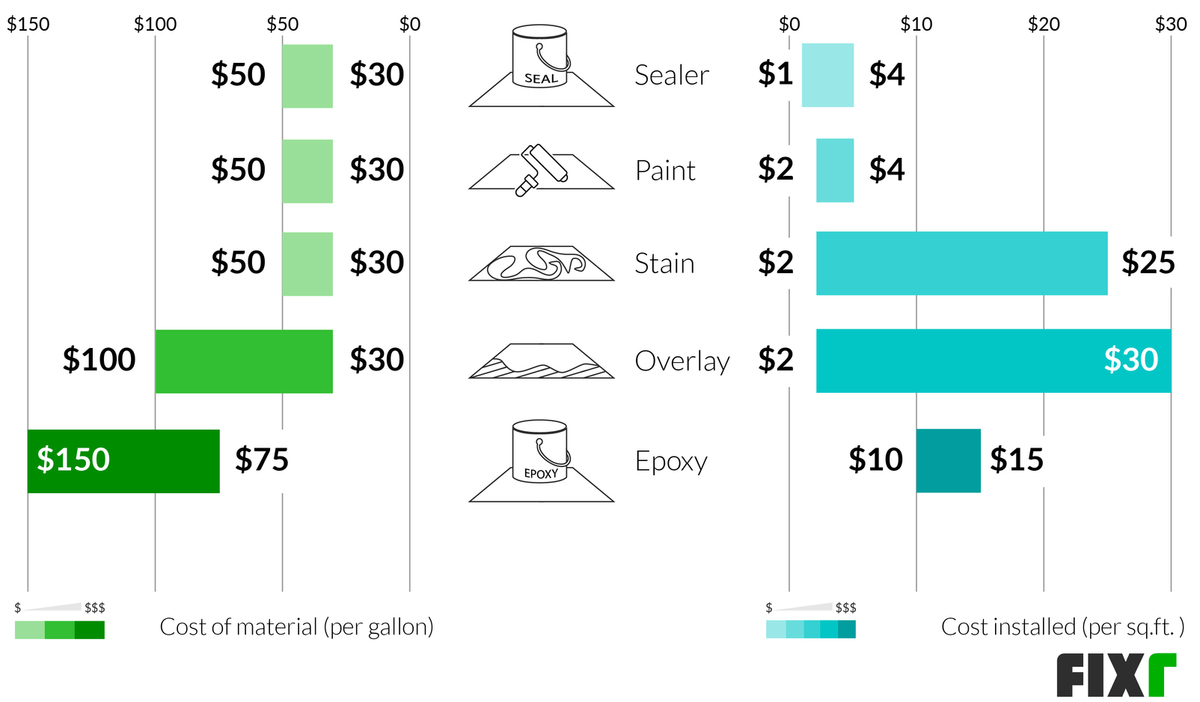

Concrete Floor Coating Cost by Material

Many different types of coating can be used to protect and enhance your concrete floor. Each one is applied differently, and each one can give your floor both a distinctive appearance and a variety in how it performs long term. Each material has a different price for the material itself and the cost to apply it.

| Material | Cost of Material | Cost per sq.ft. Installed |

|---|---|---|

| Sealer | $30-$50/gallon | $1-$4/sq.ft. |

| Paint | $30-$50/gallon | $2-$4/sq.ft. |

| Stain | $30-$50/gallon | $2-$25/sq.ft. |

| Overlay | $30-$100/gallon | $2-$30/sq.ft. |

| Epoxy | $75-$150/gallon | $10-$15/sq.ft. |

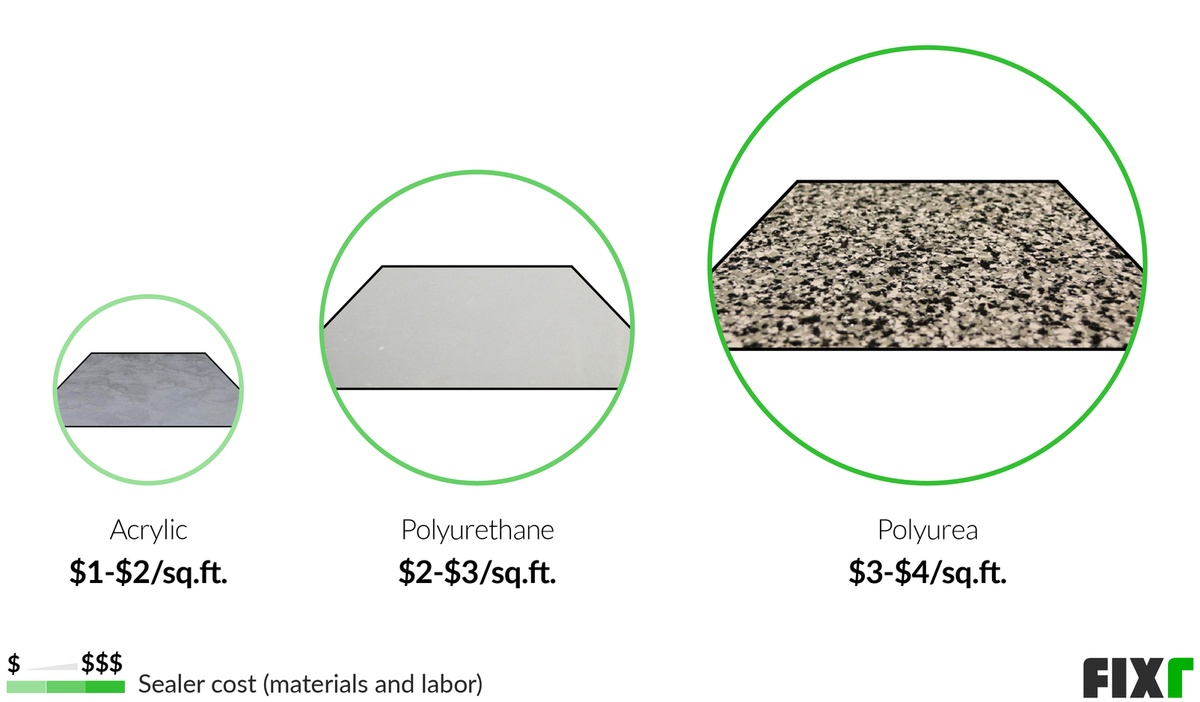

Cost to Seal a Concrete Floor

There are several different types of concrete sealers. Concrete is porous, which means that unless those pores are sealed up with some other material, the concrete can absorb liquids and stain. Sealers prevent this by keeping liquids and debris on the surface, where they can be cleaned away. There are three fundamental types of concrete sealers: acrylic concrete sealer, polyurethane concrete floor coating, and concrete floor coating. Polyurethane is the longest-lasting of the three, while polyurea has the fewest VOCs--volatile organic compounds, causing lung irritation and headaches in some people. Acrylic is the lowest price and the simplest to apply. Each sealer has its attribute to consider. In terms of value, polyurethane's long-lasting results give the best value. For those who worry about VOCs or odors, polyurea is the best choice. Those who want to sell quickly on a budget may want to choose an acrylic. All sealers give you a glossy or matte finished, depending on the one you choose. They are not designed to change the floor's color, but you can apply a sealer on top of a stain to change the floor's color. On average, sealers cost between $1 and $4 per square foot, with acrylic being the least expensive at $1 per square foot installed and the polyurea coating cost per square foot being the highest at $4 installed.

| Sealer Type | Cost (Materials and Labor) |

|---|---|

| Acrylic | $1-$2/sq.ft. |

| Polyurethane | $2-$3/sq.ft. |

| Polyurea | $3-$4/sq.ft. |

Cost to Paint a Concrete Floor

Concrete paint isn't strictly painted like you would apply to the wall. In fact, it's in fact a kind of epoxy. The majority of concrete paints are made up of about 40% epoxy that is mixed with solvents to make it more spreadable. So, while individuals describe it as paint, this approach likewise passes thin coat epoxy. There are high gloss concrete paints and those that can include some "chips" sprayed into the paint after application to provide it better toughness and texture. Painted concrete floors cost less than thick coat epoxy ones however have expenses that resemble stains. The advantage is that with the paint, you do not need to put a sealant on top of the color. Concrete paint is available in a range of different colors and colored chips for varying appearances. Concrete paint rates start at $30 to $50 per gallon or around $2 to $4 per square foot installed.

Stained Concrete Floors Cost

Staining permanently modifies the color and look of the concrete. There are 2 fundamental types of stain, water-based and acid-based. Acid staining is in some cases also described as acid engraving the floor. Stain can be used in a number of ways, which impacts the cost. You can have a single coat of stain used, which has an expense of around $2 per square foot. You can likewise apply several coats of stain to create distinct colors, patterns, and looks. In this case, some of the stain may be used, then wiped away in locations to change its appearance. This type of stain expenses as much as $25 per square foot, depending upon the color and the pattern achieved. Stencils, multiple color accumulations, and repeated patterns cost more than two-color floors or random color placements.

Polymer Modified Concrete Overlay

Homeowners typically need to coat their concrete floors since the floor is breaking, settling, or has actually suffered stains from spills and an unsealed surface. If your concrete shows indications of a great deal of wear, then a polymer-modified overlay is the very best option for coating it. This overlay includes polyurethane, so it produces an extremely hard, long-lasting, and long-wearing topcoat surface. The density of the overlay assists seal up cracks and small depressions in the concrete's surface, so you have a more level, resilient ended up the floor. This finish is usually sprayed on and expenses around $2 per sq. ft. for strong color. However, if you prefer, you can have the floor sprayed in various colors or patterns to offer it a fresh new look. Doing so increases the cost of the task to as much as $30 a square foot usually.

Epoxy Concrete Floor Cost

While concrete paint is technically a kind of epoxy and includes about 40% epoxy solids, it's also possible to coat your floor in 100% epoxy. This produces a much thicker, more resilient, and longest-lasting floor coverage. This is called a thick coat epoxy. It assists level little depressions and uneven floors and fills in little fractures. This kind of flooring coating comes in several various colors and has ornamental and colorful chips like concrete paint. The most significant difference is that this floor coating is a complete 10 ml thick, which supplies a lot more durable and longer using surface. It is possible to develop patterns or achieve metal looks and high gloss finishes with epoxy. Epoxy flooring coating costs per square foot are around $10 to $15 installed.

Cost of Refinishing Concrete Floors

Old concrete floors can stain, fracture, and otherwise wear down in time. This does not indicate that they're unstable or that they need to be changed, nevertheless, simply that the surface may need refinishing to look their best. There are numerous methods to go about refinishing concrete flooring. Using a flooring coating is one choice. Staining, painting, or using either an overlay or a thick coat of epoxy can refinish the surface of the floor to offer it a different look. Concrete can be ground down and polished, leaving its original color undamaged.

The expense of refinishing the floor comes primarily from the level of finish you need. A standard resurfacing and repairing expenses between $4 and $6 per square foot. Polishing costs between $3 and $5 per square foot for a polish and up to $30 per square foot if you are first staining the floor in a pattern or in layers and then polishing. For a 500 sq. ft. floor, this makes the cost range of refinishing in between $2,000 and $15,000.

Cost to Stain Concrete Floors Indoors

Staining is among the more appealing finishes you can offer to concrete flooring. By developing the discolorations in layers, you offer the flooring a wide range of various appearances, from a texture that resembles stone and wood to stenciled surfaces in detailed patterns. In most cases, the stained flooring is topped with a high gloss finish, providing it a polished, refined look.

The cost of staining an interior concrete floor differs depending on the level of stain. A single color over the whole flooring at the same time costs about $2 per square foot. If you choose to do a more intricate stain, a layered stain to imitate stone, or utilize stencils, your expenses per square foot can approach $25 per foot.

Cost to Stain a Concrete Basement

If you are completing your basement, staining your concrete floor is a fantastic alternative. This eliminates the problems that some other materials have with being installed below grade and offers your basement an unbelievable variety of various appearances and looks. Stains can be layered on one another to give your basement floor depth and interest. Stains have a wide range of costs depending upon the type. A single coat of stain in a solid color is around $2 per square foot. A complex design that uses stencils or creates a pattern with various colors can cost as much as $25 per square foot. The average basement is around 1,000 sq. ft, making the expense of staining it in between $2,000 and $25,000, depending upon the stain you utilize.

Garage Floor Coating Cost Per Square Foot

Coating a garage flooring is an excellent idea to safeguard it from wear and spills like oil or gas. The most common garage floor coating is epoxy. While you can use discolorations and paints, a thick coat of epoxy offers your garage flooring the longest lasting protection from oil spills and the weight of your car. The epoxy garage floor expense per square foot is around $10 to $15 a square foot. For a two-car garage, this comes out to around $5,760 to $8,640.

If you do not utilize your garage for cars and truck storage, you can use other kinds of concrete coatings. Garage floor painting costs with thin coat epoxy are around $2 to $4 per square foot or around $1,152 to $2,304 for a two-car garage.

Basement Epoxy Floor Cost

Basements can be finished with either a thin coat of epoxy-- concrete paint-- or a thick coat of epoxy. Both offer long-lasting protection for your basement floor in addition to various colors, and when it comes to thick coat epoxy, different styles. If you use concrete paint, your costs will be around $2 to $4 per square foot or $2,000 to $4,000 for a 1,000 sq. ft. basement. If you use a thick coat epoxy, your costs will be $10 to $15 per square foot or $10,000 to $15,000 for the average basement floor

Concrete professional ending up a concrete flooring.

Labor Cost of Concrete Floor Coating

Labor costs for installing a concrete floor coating differ depending on the kind of coating you have actually done. Most expenses estimated include both the labor and the materials. The product expense per square foot for basic sealants can be less than $0.50 per foot, with labor comprising the balance.

The more complex the pattern, the higher the expenses for labor will be. This is why the cost for a complicated pattern utilizing a stain can be as much as $30 per foot. The product expenses may only be $0.50 to $4 per foot, but the labor can be up to $16 to $18 per square foot, with labor expenses starting around $1 per square foot for simple jobs. The more complex the pattern, the greater the labor cost will be. For this reason, in a lot of circumstances, the provided quote will be for the ended up job, consisting of both material and labor. An overall cost range on average is $2 to $30 per square foot for most of the floors.

Concrete Floor Primer

Some floorings that are in poor condition may need a primer before being completed. The guide helps the epoxy of the paint adhere better to the flooring. Likewise, it assists level small indentations and fill small cracks. This means that the last coat goes on more smoothly.

Primers are usually only utilized for concrete paints. They are not utilized with spots and are not required with thick coat epoxy or overlays, which are both substantially thicker and able to level the floor on their own. If you need a primer included, it increases expenses by another $1 to $2 per square foot, installed.

Enhancement and Improvement Costs

Concrete Repair Cost

Concrete is a fairly durable material, however it can develop problems with time, such as settling, sinking, and breaking. The expense of concrete repair differs depending on the problem. Many small problems can be fixed for $2 to $4 per square foot. Larger problems, nevertheless, can cost as much as $10 or $12 per square foot, depending upon the seriousness of the problem.

Additional Considerations and Costs

While many people think of polyurethane as "urethane," you wish to ensure that the product you pick for your concrete is genuine polyurethane if that's the product you pick. Constantly search by its real name to make sure you're getting all the products readily available.

Concrete requirements time to cure. New concrete requirements to be entirely treated prior to it can be painted or stained. Otherwise, the moisture in the concrete might end up spoiling the finish. Always wait a minimum of six months before coating brand-new concrete.

Concrete coatings can be clear, or they can be available in a vast array of different colors and styles. Even sealants can be tinted if you desire to enhance the color of your concrete. This can be an excellent alternative if your existing concrete flooring is stained or stained.

If you select to paint or stain your flooring yourself, your expenses can be much lower than $1 per square foot for a lot of sealers, and around $1 to $2 per square foot for other types of finishes, because the majority of the cost for some coatings is in labor.

Whether it’s in a basement, a garage, or the main floor of a house, many homeowners have at least some type of concrete flooring in their house. Concrete is a mix of cement and binders that forms a smooth, hard, and durable surface when cured. Concrete lasts for many years, but it needs to be properly attended to prevent cracks, staining, and wear and tear. Part of that care is either sealing or coating your concrete floor with a long-wearing topcoat.

You can coat your concrete floor in numerous ways. Some sealers and stains give it a new color and appearance, while others impact its longevity and do not alter its appearance in any way. These variations in coatings, coupled with the reality that concrete floors can be used in various areas and come in sizes, means that there is also a wide range of costs associated with coating a concrete floor. The national average cost range is $1,150 to $4,000, with most homeowners spending around $2,500 on an epoxy floor coating for a two-car garage floor. The project’s lowest cost is around $400 for a single coat of acrylic sealer on a single-car garage floor. This project’s highest cost is around $12,000 for a highly polished polymer overlay finish on the concrete flooring of a 1,000 sq. ft. loft.

| Concrete Floor Coating Cost | |

|---|---|

| National average cost | $2,500 |

| Average range | $1,150 - $4,000 |

| Minimum cost | $400 |

| Maximum cost | $12,000 |

Concrete Floor Coating Cost by Project Range

Concrete Floor Coating Cost by Material

Many different types of coating can be used to protect and enhance your concrete floor. Each one is applied differently, and each one can give your floor both a distinctive appearance and a variety in how it performs long term. Each material has a different price for the material itself and the cost to apply it.

| Material | Cost of Material | Cost per sq.ft. Installed |

|---|---|---|

| Sealer | $30-$50/gallon | $1-$4/sq.ft. |

| Paint | $30-$50/gallon | $2-$4/sq.ft. |

| Stain | $30-$50/gallon | $2-$25/sq.ft. |

| Overlay | $30-$100/gallon | $2-$30/sq.ft. |

| Epoxy | $75-$150/gallon | $10-$15/sq.ft. |

Cost to Seal a Concrete Floor

There are several different types of concrete sealers. Concrete is porous, which means that unless those pores are sealed up with some other material, the concrete can absorb liquids and stain. Sealers prevent this by keeping liquids and debris on the surface, where they can be cleaned away. There are three fundamental types of concrete sealers: acrylic concrete sealer, polyurethane concrete floor coating, and concrete floor coating. Polyurethane is the longest-lasting of the three, while polyurea has the fewest VOCs--volatile organic compounds, causing lung irritation and headaches in some people. Acrylic is the lowest price and the simplest to apply. Each sealer has its attribute to consider. In terms of value, polyurethane's long-lasting results give the best value. For those who worry about VOCs or odors, polyurea is the best choice. Those who want to sell quickly on a budget may want to choose an acrylic. All sealers give you a glossy or matte finished, depending on the one you choose. They are not designed to change the floor's color, but you can apply a sealer on top of a stain to change the floor's color. On average, sealers cost between $1 and $4 per square foot, with acrylic being the least expensive at $1 per square foot installed and the polyurea coating cost per square foot being the highest at $4 installed.

| Sealer Type | Cost (Materials and Labor) |

|---|---|

| Acrylic | $1-$2/sq.ft. |

| Polyurethane | $2-$3/sq.ft. |

| Polyurea | $3-$4/sq.ft. |